Cotton has been an important crop for thousands of years and is considered to be one of the oldest and most widely used natural fibers. It is used extensively in the textile industry for producing clothing, home furnishings, and industrial products. Textile fibers can be classified into different categories based on the origin which we have covered here. Cotton fibers are natural fibers. In this article, we will explore the chemistry, structure, properties and uses of cotton fibers, the various types of cotton, and the impact of cotton production on the environment.

Cotton fiber chemistry and structure

Cotton fibers are made up of cellulose, a natural polymer that is composed of long chains of glucose molecules. The cellulose molecules are arranged in a way that creates a strong and flexible fiber.

Chemically, cotton fibers are made up of approximately 90% cellulose, with the remaining 10% consisting of other compounds such as waxes, pectin, and proteins. The cellulose in cotton fibers is a linear polymer made up of repeating units of glucose molecules, with each unit connected by beta 1-4 glycosidic bonds. These long chains of glucose molecules are arranged in a crystalline structure, which gives cotton fibers their strength and durability. The interchain hydrogen bonding between polymeric chains of cellulose is so strong that it becomes resistant to many solvents.

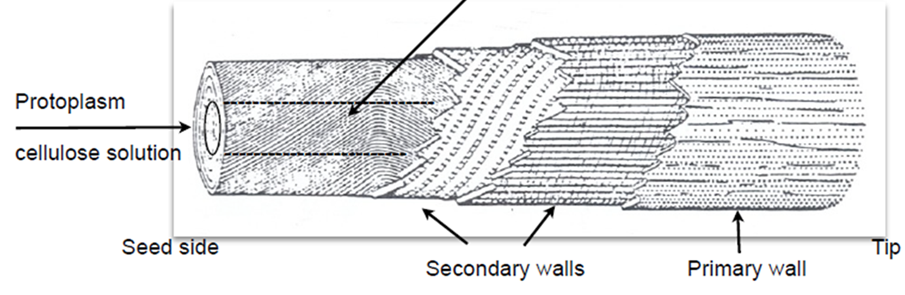

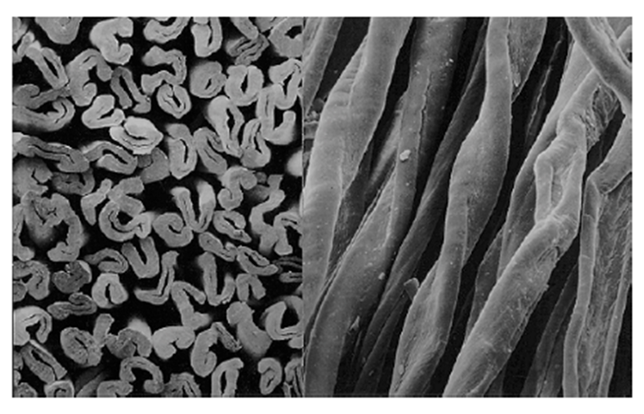

The structure of cotton fibers can be divided into two main parts: the cuticle layer and the inner fiber. The cuticle layer is a thin layer of wax and pectin that surrounds the fiber and protects it from damage. The inner fiber is made up of the cellulose chains arranged in a helical structure that runs along the length of the fiber. The fiber has a hollow cavity in the center of the fiber which gives it bean like cross sectional shape.

Overall, the chemical and structural properties of cotton fibers make them a versatile and valuable natural resource that is widely used in the textile industry.

The internal cavity of the fiber collapses when cotton boll is opened and fiber is dried. This results in tubular shape and bean like cross section of the fiber as shown in the figure:

Cotton fiber properties and characteristics

Cotton fibers have a number of physical, chemical, and comfort properties that make them highly valued in the textile industry. In this note, we will explore the various properties of cotton fibers in more detail.

Physical Properties

- Length: Cotton fibers are typically long and fine, with a high degree of strength and elongation. The length of cotton fiber can range between ½ inch to 2 inches. The length and fineness of cotton fibers can vary depending on the variety of cotton, with longer and finer fibers generally being associated with higher quality cotton. It is because of this reason that PIMA and Egyptian cotton is considered high quality cotton. Cotton fibers are also highly absorbent, which makes them suitable for use in a wide range of textile products. Additionally, cotton fibers have a natural luster that gives them a soft, luxurious appearance.

- Fineness: The fineness of the fiber is represents the diameter of the fiber and is termed as “mic” value which is defined as number of micrograms per inch of the fiber. The fineness ranges between 3 to 6 microgram per inch.

- Strength: Cotton fibers have moderate strength in the range 26-44 cN/tex. In wet condition, cotton fibers demonstrate 20% more strength than in dry state.

- Elongation: Cotton fibers have elongation at break of 5-10%.

- Hydrophilicity: Due to hydroxyl groups present in chemical structure, cotton fibers can absorb moisture. Moisture regain of cotton fibers is 8.5% at standard conditions.

- Heat conductivity: High heta conductivity, therefore, gives cool feeling during summer

- Heat: Cotton fibers do not melt, decompose at temperature greater than 150° giving rise to carbonaceous char.

- Flame: Cotton fibers burn readily with “burning paper” smell. Their LOI is 18%.

- Sun exposure: Sensible to photodegradation, long term sun exposure can degrade them

Chemical Properties

The chemical composition of cotton fibers is primarily cellulose, a natural polymer composed of long chains of glucose molecules. Cotton fibers are also composed of other compounds, including waxes, pectin, and proteins. The high cellulose content of cotton fibers makes them resistant to many chemicals, which makes them suitable for use in a variety of industrial products.

- Acids: Cotton fibers resist to cold diluted mineral acids but are destroyed by concentrated acids. Concentrated acids cause hydrolysis by cleaving the 1-4-glycosidic bonds.

- Bases: resist well to caustic alkalis, cold concentrated alkalis form alkali-cellulose and are used in mercerization of cotton fibers

- Solvents: Resists well to organic solvents used in dry cleaning

- Oxidants: Resist to hypochlorites, chlorites and hydrogen peroxide used in bleaching, although strong oxidizing agents forms the expected aldehyde and ketone, and carboxyl groups (oxicellulose)

- Reductants: Resist to reductants

- Dyeing: Cotton fibers can be easily dyed with most dyes except acids and disperse dyes

- Biodegradation: not inherently resistant to molds and bacteria; they are also degraded by cellulase enzymes

Comfort Properties

Cotton fibers have a number of comfort properties that make them ideal for use in clothing and other textile products. One of the most important of these properties is breathability. Cotton fibers allow air to circulate freely, which helps to regulate body temperature and prevent overheating. Additionally, cotton fibers are highly absorbent, which means they can absorb and wick away moisture from the skin, keeping the wearer feeling dry and comfortable.

Cotton fibers are also hypoallergenic, which means they are less likely to cause allergic reactions than other fibers such as wool or synthetic fibers. This property makes cotton a popular choice for people with sensitive skin or allergies.

In summary, cotton fibers have a range of physical, chemical, and comfort properties that make them highly valued in the textile industry. The physical properties of cotton fibers, such as their length, fineness, and strength, make them ideal for use in a wide range of textile products. The chemical properties of cotton fibers make them resistant to many chemicals, which makes them suitable for use in industrial products. Finally, the comfort properties of cotton fibers, such as their breathability and absorbency, make them ideal for use in clothing and other textile products.

Types of cotton fibers

There are several types of cotton fibers, each with its own unique properties and characteristics. Here are some of the most common types of cotton fibers:

Upland cotton

This is the most common type of cotton fiber and accounts for around 90% of the world’s cotton production. Upland cotton fibers are relatively short and have a diameter of around 20 to 30 microns.

Pima cotton

Also known as extra-long staple (ELS) cotton, Pima cotton fibers are longer and stronger than upland cotton fibers. Pima cotton is grown primarily in the United States, and its fibers are prized for their softness, strength, and durability.

Egyptian cotton

This type of cotton fiber is grown primarily in Egypt and is known for its exceptional softness, strength, and luster. Egyptian cotton fibers are longer than upland cotton fibers and have a diameter of around 18 to 20 microns.

Sea Island cotton

This is a rare and expensive type of cotton fiber that is grown primarily in the West Indies. Sea Island cotton fibers are exceptionally long and fine, with a diameter of around 10 to 15 microns.

Organic cotton

This is cotton that is grown without the use of synthetic pesticides or fertilizers. Organic cotton fibers are similar in size and quality to upland cotton fibers.

Colored cotton

Colored cotton is another type of cotton that is grown in various shades, including green, brown, and red and is naturally colored.

Bt Cotton

Bt-Cotton toxin, a family of toxins originally derived from soil bacteria, is used to genetically engineer natural cotton. The plant thus produces its own Bt toxin to destroy the bollworm. Bollworm is killed when it ingests the cotton plant which reduces use of pesticides.

The type of cotton fiber used in textiles can have a significant impact on the quality, durability, and comfort of the finished product. By selecting the right type of cotton fiber for a particular application, textile manufacturers can ensure that their products meet the highest standards of quality and performance. Different types of cottons can be mixed together to achieve cost-performance balance.

Processing of cotton fibers

Cotton fibers go through several processes before they can be used in textiles. The first step is ginning, which involves separating the cotton fibers from the seeds. Next, the cotton fibers are converted into yarn through a yarn manufacturing process. The yarn is converted into fabric in a weaving unit. The fabric is then dyed, printed, finished and converted into final product. Thus it undergoes through entire chain of textile manufacturing processes.

Cotton fiber uses and applications

Cotton is one of the most versatile and widely used natural fibers in the world, with a wide range of applications in textiles, paper products, medical supplies, and more. Here are some of the most common uses of cotton fibers:

Textiles: The cotton fibers are mostly used to produce textiles, including clothing, bedding, towels, and other household fabrics. Cotton fibers are prized for their softness, breathability, and durability, making them a popular choice for a wide range of apparel and home textile products.

Paper products: Cotton fibers are also used to produce high-quality paper products, including stationery, currency, and fine art paper. Cotton fibers are ideal for paper production because they are strong, absorbent, and have a high degree of purity.

Medical supplies: Cotton fibers are used to produce a wide range of medical supplies, including gauze, bandages, and surgical dressings. Cotton fibers are ideal for medical applications because they are hypoallergenic, absorbent, and biodegradable.

Industrial products: Cotton fibers are used to produce a wide range of industrial products, including oil and gas filters, insulation, and automotive parts. Cotton fibers are prized for their strength, durability, and ability to absorb liquids and gases.

Food products: Cottonseed oil is a popular cooking oil that is derived from cottonseeds, the small, hard seeds that are produced by cotton plants. Cottonseed oil is high in monounsaturated and polyunsaturated fats, making it a healthy alternative to other cooking oils.

Overall, cotton fibers are a vital component of many different products and industries, and their versatility and wide range of applications make them an essential part of the global economy.

Environmental impact of cotton production:

While cotton is a valuable crop, its production can have a negative impact on the environment. Cotton requires large amounts of water, and the use of pesticides and fertilizers can lead to soil degradation and contamination of water sources. However, there are sustainable cotton production practices that can help reduce the environmental impact of cotton production, such as the use of organic farming methods and the implementation of water conservation practices.

Conclusion

Cotton fibers are natural fibers that are used in a wide range of products. Cotton fibers are composed of cellulose. The physical and chemical properties of cotton fibers make them ideal for use in textiles, and there are several different types of cotton fibers that are used in various products. While the production of cotton can have a negative impact on the environment, there are sustainable production practices that can help mitigate this impact. As the demand for sustainable products continues to grow, it is likely that cotton production will become more sustainable in the future. The detailed sciemtific literature about cotton fibers can be studied here.