We are familiar with different types of textile fibers and also know various processes to convert fibers into yarns. Yarns are either staple spun yarns or filament yarns. Staple spun yarns are made from small length fibers whereas filament yarns consist of filaments which are fibers of continuous or unlimited length. The terms partially oriented yarn (POY), fully drawn yarn (FDY) and drawn and textured yarn (DTY) are commonly used for polyester filament yarns. However, any synthetic fiber yarn can be either partially oriented (POY), fully drawn (FDY) or drawn and textured (DTY). But what is the difference between POY, FDY and DTY yarn?

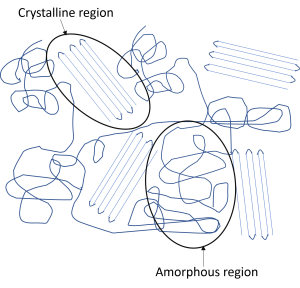

Partial or full orientation is related to the structure of the filament or yarn and refers to the orientation of the crystalline domains or regions along the yarn axis or length of the yarn. Polymers consist of large chains of molecules that are made of small units known as monomers. Hundreds or thousands of monomers can bond with each other to form large polymer molecules or chains. A crystalline region is a region or small domain within the polymer bulk where polymeric chains are ordered compared with less ordered regions known as amorphous regions. These crystalline regions or domains are embedded within the amorphous or less ordered regions of the polymer as shown in the figure below:

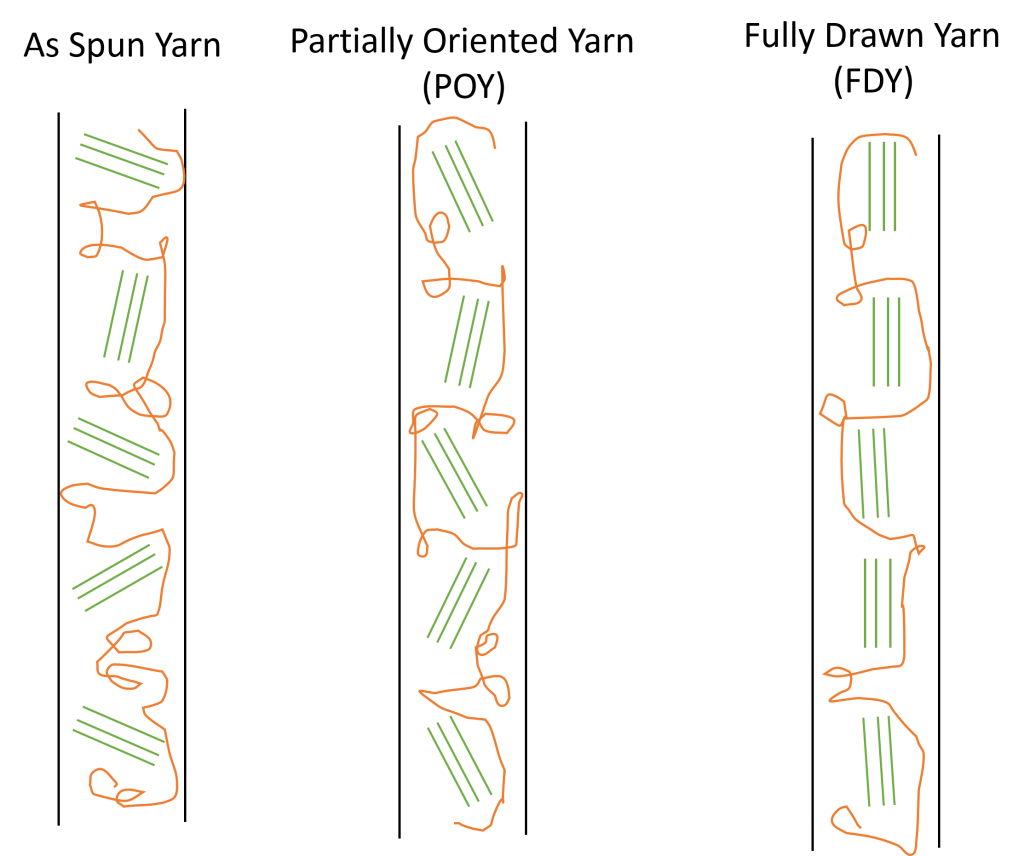

When a polymer is converted into a fiber by passing the melt or solution of the polymer through a spinneret, a fiber or filament is formed. While passing through the spinneret holes, the crystalline regions or domains are somewhat oriented along the fiber or filament axis. However, the orientation is not enough in as spun filaments (just extruded filament) to give sufficient strength to the filaments.

After spinning, post spinning operations mainly drawing is performed to improve the orientation and hence strength of the filament. In the drawing process, filaments are stretched to improve the orientation of the crystalline domains in the as spun filaments or yarns along the filament or yarn axis. It is the extent of this drawing process that defines the as spun, partial or fully oriented yarns.

The post spinning drawing process can be carried out either in the cold state known as cold drawing or in a hot state known as hot drawing. In a hot state, the polymer becomes soft and can be stretched and oriented more than in a cold state. Hot drawing can result in the heat setting the polymeric chains and making more stable filaments.

When a polymer melt or solution is just extruded from the spinneret, it is known as as-spun fiber or filament. As-spun filaments have very poor strength because of the poor orientation of crystalline domains.

As spun or just extruded filament may have a drawing effect on its way to the bobbin before winding while passing through take-up rollers resulting in partially oriented yarn (POY) In light of the above explanation partially oriented yarns (POY), fully drawn yarns (FDY) and draw textured yarn (DTY) can be explained as follows:

Partially oriented yarn (POY)

In partially oriented yarn (POY), the crystalline domains of the polymer are partially oriented along the yarn or filament axis. However, crystalline domains are not fully oriented along the yarn axis in partially oriented yarn (POY). This partial orientation imparts sufficient strength to the as spun or just extruded yarns or filaments so that these can withstand the stresses of downstream processes to be converted into fabric. POY is the first form of yarn when a polymer is converted into a filament.

The production process of partially oriented yarn (POY)

In the case of melt spinning, the polymer chip is first melted and then forced through a spinneret which is similar to a bathroom shower. The molten polymer comes out of spinneret holes similarly as water streams come out of the shower. The molten polymer is then dried with the help of quenched or cold air to solidify the molten filament. A drawing effect may happen while the filament is passed over take up roller and wound onto a bobbin.

Properties and applications of partially oriented yarn (POY)

The degree of crystallinity of partially oriented yarns (POY) is up to 5 %. It should be noted that when a yarn or filament is stretched, it gets elongated. The more yarn is stretched, the more it is elongated leaving a lower extent of further elongation. Since partially oriented yarn (POY) is not fully oriented or stretched, it has about 80% elongation capacity left within its structure. It is due to this low crystallinity that the shrinkage in POY yarn is very high and may be up to 70 %.

POY yarn is available in semi-dull and bright lusters. Semi-dull luster is obtained by mixing titania in the polymer melt. Other than semi-dull and bright lusters, dyed yarn can also be obtained by mixing a dye in the polymer dope or melt known as dope-dyed polyester yarn. Dope-dyed POY yarn offers the advantage that the fabric dyeing process is not required because the fabric has been produced using already dyed yarn thus making dope-dyed yarn more eco-friendly compared with undyed POY yarn.

Partially oriented yarn (POY) is used in various woven and knitted fabrics to make ladies’ and gents’ clothing, home textiles and other products. POY can be further used in the production of texturized yarn known as drawn textured yarn (DTY). Textured yarn is usually produced in separate units which buy POY from producers.

Fully drawn yarn (FDY)

In fully drawn yarns, the crystalline domains in the polymer are significantly oriented along the yarn axis as a result of the drawing or stretching process. This makes FDY yarn stronger as compared with POY yarn. FDY is also known as polyester filament yarn (PSF) or spin drawn yarn (SDY).

Properties and applications of fully drawn yarn (FDY)

In fully drawn yarn, the possibility of further elongation is low and is about 40% or less. Thus FDY is more stable than POY yarn. Due to the high degree of orientation of polymeric chains, the degree of crystallinity is high compared with POY and can be up to 40 %. FDY is also available in semi-dull and bright lusters. Most filament cross section is circular, however, it can also be trilobal or triangular which has brighter luster and is used in making curtains.

Due to high crystallinity, the shrinkage in the FDY is very low compared with POY and is usually up to 12 %. Fully drawn yarn (FDY) is used in making high strength textiles and fabrics such as home textiles, sportswear, automotive and other technical textiles. FDY is also used in sewing and embroidery threads. FDY is also used in Rachel blankets. Mostly FDY is used as flat yarn and thus to manufacture non-textured fabrics. FDY is also used in Chanel yarns, curtains, crepe and lace fabrics. The degree of orientation of these crystalline domains along the yarn axis is shown in the following scheme for as-spun, POY and FDY yarns:

Difference between POY and FDY yarn

In light of the above discussion, the main difference between POY and FDY yarn is the degree of orientation or stretching of the yarn. POY is partially stretched or oriented yarn where as DFY is fully stretched or oriented yarn.

Drawn and textured yarn (DTY)

Drawing is not the only post spinning operation, texturization of the filament or fiber surface can also be done after spinning. Texturization means giving some effect to the surface of the otherwise flat fiber or filament. For example, introducing crimp or twist in the fiber structure is an example of surface texturization of fibers or filaments.

Texturization of fibers or filaments increases the bulkiness of yarn. Texturization is usually carried on POY, however, FDY can also be texturized. Usually, FDY is used as flat yarn. Post spinning drawing and texturization can be carried out simultaneously. Depending upon the type of texturization, there can be different types of DTY yarns like intermingled yarns or air textured yarn (ATY) which will be covered separately.

Difference between DTY and FDY yarn

In light of the above discussion, the difference between DTY and FDY is the texturization process. FDY is only stretched or fully drawn yarn whereas DTY is drawn as well as textured yarn. During the draw textured yarn process, texturization can be the introduction of crimps in the form of twists, loops or interlaces which give bulkiness to the DTY yarn.

In conclusion, POY is partially oriented yarn, FDY is fully drawn or oriented yarn and DTY is drawn or stretched and textured yarn.