Core spun yarns are the versatile yarns for the textile industry. Yarn is a linear assembly of textile fibers used to make knitted or woven fabrics. It is made from fibers that are spun together to create a long, continuous strand that can be woven, knitted, or crocheted into various fabrics. There are different types of yarns and yarn manufacturing processes which we have already covered in another article. The yarn can be made by simply twisting fibers together in a helical conformation using various spinning techniques. But there are some other types of yarns which can be made by combining both staple and filament fibers. One such type of yarn that has gained popularity in recent years is the core spun yarn.

In this article, we will discuss the production process, types, applications, advantages, and disadvantages of core yarns.

Core spun yarn manufacturing process

These yarns are made by wrapping fibers around a central core. It is due to this reason that these are called core spun yarns. The core can be made of a variety of materials, including cotton, polyester, or even spandex. Most commonly a filament is used as core material. Similarly, the fibers that are wrapped around the core can be made of any material, such as wool, cotton, or silk or any other synthetic staple fibers.

The core yarns can be produced using conventional ring spinning machine is used to produce most of the yarns used in different products. Therefore, the process is similar up to the formation of roving and feeding the roving to the drafting system or the ring frame. On ring frame, the fibers are first drafted, which means they are pulled out and elongated to make them thinner and more uniform. Then, they are combined with the core material where thin assembly of fibers get wrapped on the core. Instead of filament, a pre spun yarn can also be inserted within the core of the yarn to tailor the desired properties.

Different techniques of production

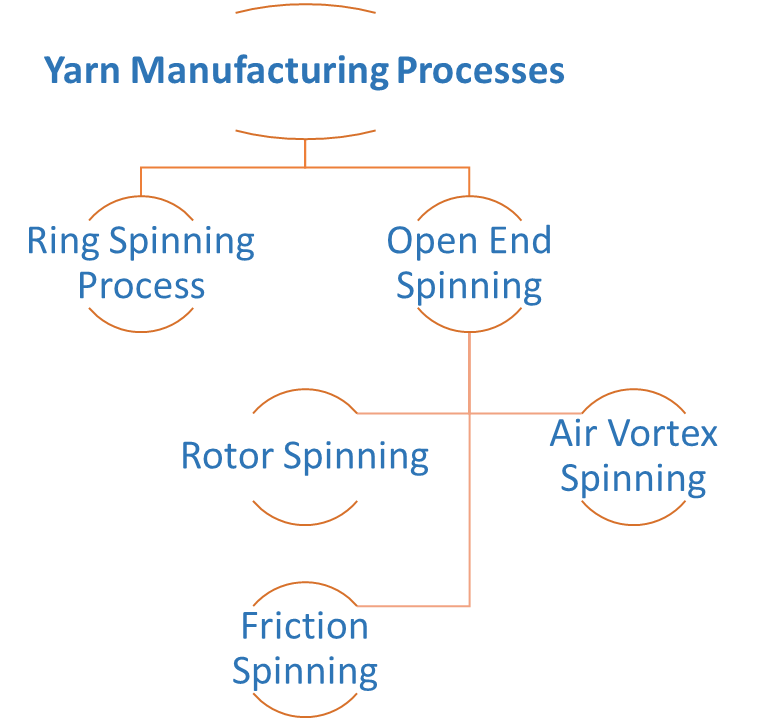

There are several techniques used to produce core spun yarns, including conventional ring spinning mentioned above, wrap spinning, split roving, and direct core spinning. Wrap spinning involves wrapping the fibers around the core after they have been spun. Split roving involves splitting the roving into two or more parts and spinning them around the core. Direct core spinning involves spinning the fibers directly onto the core.

Types of core spun yarns

There are different types of core spun yarns, including single core spun yarns, double core spun yarns, multi core spun yarns, stretch core spun yarns, and hybrid core spun yarns.

Single core spun yarns have one central core, while double core spun yarns have two cores. Multi core spun yarns have more than two cores, while stretch core spun yarns have a core made of spandex or other stretchy material. Hybrid core spun yarns are made by combining different fibers and cores to create unique yarns.

Applications or uses of core spun yarns

Core yarns can be used in various industries, including apparel, home textiles, medical textiles, technical textiles, and outdoor and sports textiles. They are ideal for creating fabrics that require strength, durability, and comfort.

In the apparel industry, core spun yarns are used to make denim, socks, tights, and other clothing items that require strength and durability. In the home textile industry, they are used to make upholstery fabrics, curtains, and bedding that require durability and comfort.

In the medical textile industry, core yarns are used to make surgical gowns, drapes, and other medical fabrics that require strength and durability. In the technical textile industry, they are used to make geotextiles, protective clothing, and other industrial fabrics that require strength and durability.

Core spun yarn properties or advantages and disadvantages of core spun yarns

Core yarns have several advantages, including strength, durability, comfort, and versatility. They are stronger than regular yarns, making them ideal for creating fabrics that require strength and durability. They are also more comfortable than regular yarns, making them ideal for creating fabrics that require comfort. The key advantage of core spun yarns is that the properties of different materials can be combined in a single yarn. For example, the strength of filament can be combined with comfort of cotton fibers by wrapping cotton fibers onto the strong polyester core. Similarly elastane yarn can be produced by inserting elastane filament within the core of the yarn that makes it stretchy to give comfort and fit to different apparel products.

However, these yarns are more expensive to produce than regular yarns. Additionally, they can be challenging to produce, requiring specialized equipment and skilled labor.

Conclusion

In conclusion, core spun yarns are innovative and versatile yarns that have gained popularity in recent years. They are made by wrapping fibers around a central core, and there are several types of core spun yarns, including single core yarns, double core or even tricore yarns.

I’m truly impressed by the depth of information in your blog post on core-spun yarns! Your clear explanations of the manufacturing process, properties, and diverse applications make this a valuable resource for anyone interested in textiles. The engaging writing style and well-organized content make learning about this topic a breeze. Thank you for sharing your expertise!